Valves play a crucial role in paddleboards, and they are also one of the most vulnerable components on a paddleboard. The quality of the valve directly affects the lifespan of the paddleboard, and addressing valve issues can help you gain a larger market share.

Common Valve Structures

Common inflatable product valves include two types: screw valves and spring valves. Screw valves are typically used for larger inflatable products such as boats, kayaks, and mats. Spring valves are the choice for the majority of paddle boards on the market. They consist of four main parts: the valve body, spring valve core, sealing ring, and valve disc. The working principle involves controlling the valve's opening and closing by pressing or releasing the spring valve core.

To inflate the paddleboard, insert the pump interface into the valve, push down the spring core, and then turn the pump interface to secure the valve. The spring remains compressed at this point, and the air hole opens, allowing the paddleboard to inflate. Once the pump is removed, the spring automatically rebounds, sealing the air hole and preventing leakage. This design is known for its simplicity and ability to withstand high air pressure.

Why do Valves fail?

The reasons for valve damage primarily include the following:

Insufficient Material Quality: Valves made from low-strength materials that are not resistant to wear or corrosion can lead to issues such as abrasion, deformation, and air leakage

Foreign Objects: Foreign objects such as sand, rocks, and fine threads from cloth can infiltrate the valve's interior. This intrusion can lead to the jamming of the spring core, preventing the valve from closing correctly and consequently causing air leakage.

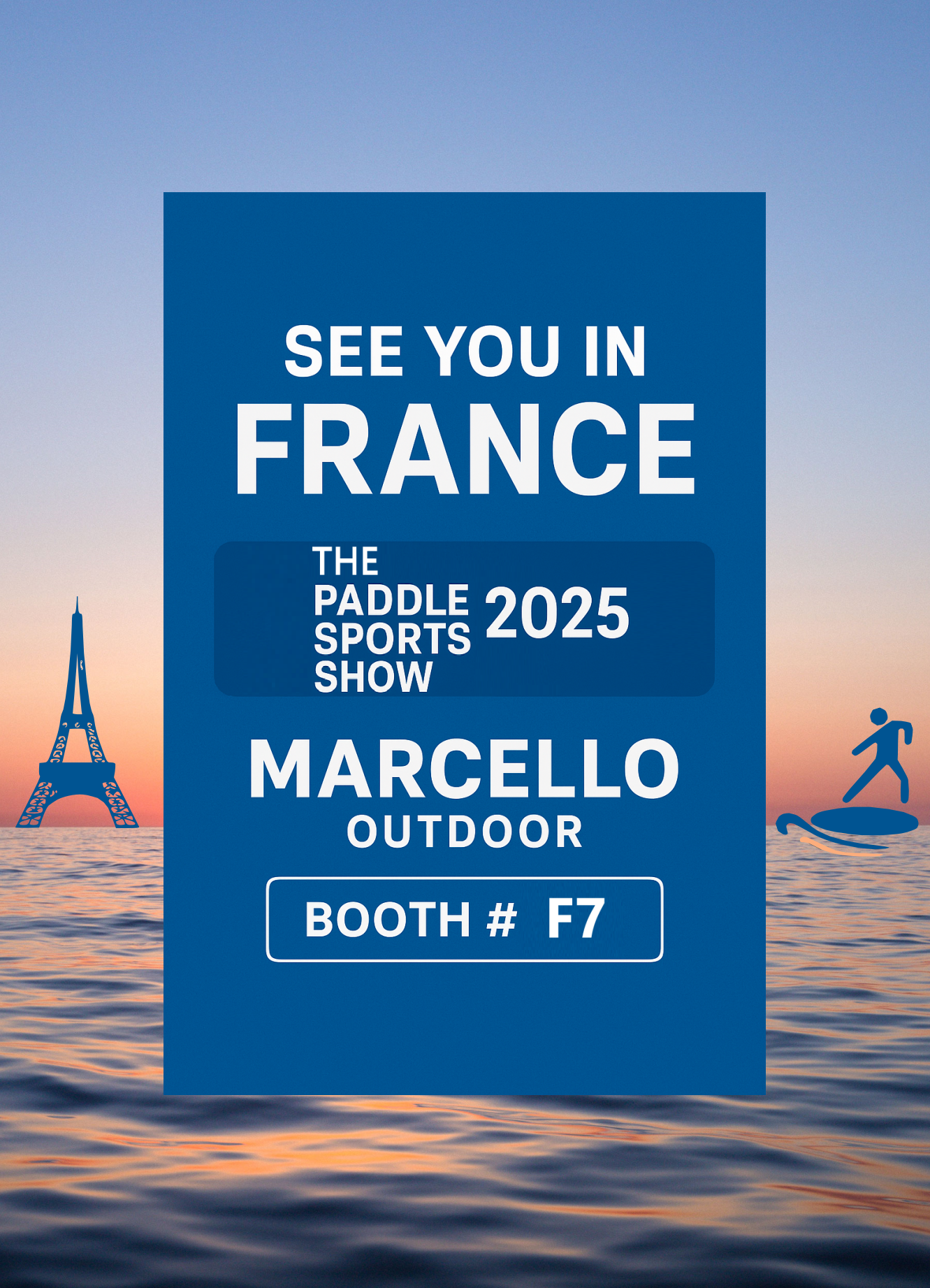

Optimizations Made by Manufacturer Marcello

To address these issues, as a manufacturer, Marcello has implemented the following optimizations:

Material Selection: Marcello has opted for Polyoxymethylene (POM) as the material for the valve core and valve body instead of the standard PVC used in regular spring valves. Additionally, Marcello uses silicone rubber for the sealing rings and gaskets rather than the commonly used Polytetrafluoroethylene (PTFE).

|

Material |

Density |

Flexural |

Tensile |

Elastic |

Hardness |

Heat |

Corrosion |

|

PVC |

81.1 - 90.5 lb/ft³ |

7250 - 11600 psi |

6525 - 8700 psi |

290 - 580 ksi |

70 - 95 Shore D |

140 - 176°F |

Acid and alkali |

|

POM |

87.9 - 89.1 lb/ft³ |

7975 - 17400 psi |

8700 - 11600 psi |

406 - 522 ksi |

82 - 87 Shore D |

176 - 248°F |

Acid and alkali |

Foreign Objects Prevention: Marcello has added an extra mesh layer into the valve design, substantially reducing the likelihood of foreign objects infiltrating the valve and causing jamming issues.

These optimizations enhance paddleboard valves' durability and improve the user experience, ensuring your paddleboarding adventures remain trouble-free.